What were the major contributors to the new productivity in the late nineteenth century?

Abstract

Rise productivity, alongside exploration, is the chief means by which mining tin can combat resource depletion. Over the past i hundred and fifty years, the mining industry has been remarkably successful in growing its productivity. Yet, since 2000, there are signs of a slowdown. Some aspects of this are clearly cyclical only at that place are increasing concerns that some of the underlying, longer term, factors which take kept productivity growing in the by are losing their force. Fundamental amongst these factors are the physical contributions that the second industrial revolution, starting time in the late nineteenth century, brought to mining, most notably in the course of larger equipment operating in larger mines. There is much give-and-take in the industry effectually the arrival of a quaternary industrial revolution and how this might 'disrupt' the sector and deliver a new heave to productivity through the promotion of intelligent mining but thus far there is niggling the evidence of such a boost. In its absence, the mining industry faces the prospect of rising costs as grades fall and waste volumes abound.

Introduction

It can safely exist said that nobody has contributed more towards the development of mineral economics in recent years than John Tilton. John combines an inquiring heed, a rigorous grasp of economic theory and the powers of a corking communicator. He is likewise somebody I am pleased to call my friend these past thirty-5 years, since we first met at a Un meeting on deep sea mining in New York in 1983.

In subsequent years, through diverse jobs, I have had the pleasure of undertaking several projects with John and sharing a number of adventures in places across the globe, including Sweden, France, Republic of austria, Chile and Nippon. I have learned an immense amount from him and, no less, take been a lucky beneficiary of his and Liz's generous hospitality.

One of the issues that has intrigued John over the years, and to which he has returned in his writings and speeches, is the issue of productivity in mining. In enquiry published past Resources for the Futurity (RFF), John, along with Hans Landsberg, provided the definitive analysis of how the Us copper industry saved itself by radically boosting its productivity in the 1980s (Tilton and Landsberg 1999). In after work, he addressed concerns that productivity in the mining industry might be in secular refuse, demonstrating that productivity in mining is inherently cyclical, with loftier prices tending to suppress productivity as companies focus on book, and with low prices tending to boost it as companies seek to reduce costs (Tilton 2014). He remained optimistic that, when the furnishings of the nearly recent smash had worked through, productivity growth in the industry would resume.

The purpose of this newspaper, equally a tribute to John Tilton, is to take a very long-term look at productivity and to see what, cutting through the natural cyclical variations in productivity, the data tell us about past trends in mining productivity and where information technology might now be headed.

Productivity is, of course, fundamental to all economic sectors as it cardinal to a country'south general economical well-beingness. John'south affiliate in the RFF written report begins with the well-known quote by Paul Krugman that 'Productivity isn't everything, but in the long run it is virtually everything. A state's ability to meliorate its standard of living over time depends almost entirely on its power to raise its output per worker'.

The notion of productivity, however, has particular significance in mining since mining operates in an industry with depleting assets. Productivity growth has first to overcome the furnishings of this before it can brand any real headway. Although much discussion on depletion focuses on the issue of grade decline in the remaining available resources, depletion goes a chip wider than this. It tin can besides take the class of college stripping ratios (the need to remove more than overburden), harder stone, more than complex mineralogy and more impurities in the ore (necessitating more processing). Furthermore, it implies the need to safely dispose of—and pay for—increasing amounts of solid and liquid wastes. In the absence of a capacity for the positive contributors to productivity to outweigh the negative effects of depletion, then costs of mineral production must rise and then, somewhen, must prices. Moreover, the nature of the commodity business hitherto, with its homogenised products, is such that producers tin can practice lilliputian by style of branding or production differentiation to help boost the value of their output. It all comes down in the end to costs and, to a significant degree, this means productivity.

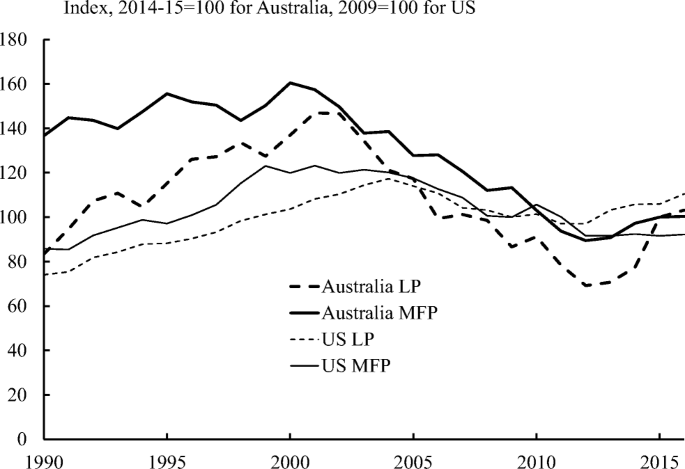

At that place have, in recent years, been some worrying developments in manufacture productivity. Since around the year 2000, productivity in mining across the globe appears to have declined, and declined significantly. Figure 1 shows indexes of labour productivity and multifactor productivity for mining in Australia and the United states since 1990. Labour productivity (LP) is a simple measure out of output per worker in mining. Multifactor productivity (MFP) is a more comprehensive indicator of productivity, which seeks to mensurate the efficiency with which capital, labour and intermediate products are converted into outputs. It is sometimes also referred to as total cistron productivity.

Productivity in the Australian and The states mining industries. Source: Australian Agency of Statistics, Estimates of Industry Multifactor Productivity, https://www.abs.gov.au; Bureau of Labor Statistics, data for 'Mining, except Oil and Gas (NAICS 212)', https://world wide web.bls.gov

Whichever measure is used—and, as Fig. ane shows, it is often the case that these measures broadly move together—the trend in recent years is clear. There are, information technology is true, some signs of a turnaround since 2012, consistent with John'southward view that productivity has a strong cyclical component and that much of the autumn in productivity shown in the figure reflects the China-induced boom in prices that occurred from around 2004. However, it is too truthful that most readings on productivity are withal a long way below their levels of 2000. Consistent with this observation, real terms operating costs for a number of major metals are still substantially higher than their pre-boom levels (Humphreys 2018). And then there is the rather awkward fact that the reject in productivity, in Australia at least, appears to accept started before the smash got under way.

Since the passing of the boom in 2012, mining companies have made growth in productivity a central plank of their efforts to boost their margins and recover the confidence of investors (BHP 2014). And nonetheless accounting and consulting firm Deloitte was 2 years later however talking virtually 'sliding productivity and spiralling costs' in the mining industry (Deloitte 2014). The consulting group McKinsey's proprietary MineLens Productivity Index (MPI), which showed a more than than 35% drib in global mining productivity betwixt 2004 and 2012, has since begun to recover, simply the recovery is weak and the index remains over 30% below the levels attained earlier the smash (Lala et al. 2016; Flesher et al. 2018). In Chile, an analysis of the land'due south copper manufacture showed at decline in MFP of betwixt 68 and 85% betwixt 2000 and 2009, although it has since recovered some basis (Solminihac et al. 2018). A more substantial recovery in mine productivity may come up in time but, for the moment at least, there still seems to be a pretty major problem. Is depletion finally getting the upper hand?

Groundwork

For something equally fundamental to the functioning of the industry, and which companies talk about such a lot, it is surprising how niggling we know well-nigh the long-run drivers of mining productivity. Partly this is near information. Most of the detailed industry data available to u.s.a. only really become back only to the 1970s. While this certainly provides interesting show of the cyclical character of productivity, as John Tilton has demonstrated in his piece of work, it provides merely express insights into longer term trends, something which is rather important when we are talking about the relationship betwixt productivity and depletion.

In their attempts to get an insight into this issue going back before the 1970s, some researchers have looked to long-run trends in mining costs and prices. Generally speaking, this inquiry, in as far as information technology tends to show no clear evidence of a long-term rise in mining industry costs and prices when expressed in constant dollar terms, does provide strong circumstantial evidence that the positive, cost-reducing elements of productivity must, for the well-nigh part, take grown sufficiently strongly to take offset the negative, toll-increasing furnishings of depletion (Barnett & Morse 1963; Manthy 1978; Barnett 1979; Humphreys 2013).

Clearly, the absence of the data which would let us to bear a thorough analysis of long-run drivers of productivity is an insurmountable hurdle. We cannot invent data where none be. Notwithstanding, getting a firmer handle on long-term trends in mine productivity really matters. It is hard to see how information technology is possible to forecast the behaviour of productivity in the time to come if we practise not know what collection it in the by. In the absence of an understanding of what lies behind trends in productivity, we are just extrapolating.

Broadly, we know the factors which shape changes in productivity. John provides a useful list of factors which drive modify in MFP (Tilton 2014).

-

Innovation and technological alter

-

Resource depletion and ore quality

-

Government regulations

-

Worker quality

-

Investment lags

-

Economies of scale

-

Capacity utilisation

-

Strikes, accidents and other unplanned production stoppages

-

Other factors, east.chiliad. management, organization and market structure

For labour productivity, i needs also to add in variations in the quantity of capital and intermediate products used for production. For MFP, these are already accounted for.

The trouble is that we do not know the precise role or the exact contribution of each of these factors. Moreover, it is axiomatic that some of these factors, like capacity utilisation and strike action, while they may exist of import for year to year variations in productivity, are non peculiarly relevant to the longer term.

Other factors, all the same, would seem to be more obvious candidates every bit contributors to long-term productivity growth. It seems probable, for example that worker quality has improved over fourth dimension every bit the work force has become amend educated and as wellness intendance has improved. Economies of calibration also seem, on the face of it, a likely candidate. And, perhaps most important of all, innovation and engineering, as embodied in the equipment and techniques available to each succeeding generation of miners, must surely be a crucial correspondent, as John acknowledges, fifty-fifty if it presents considerable problems of measurement.

In what follows, we attempt to dig dorsum a bit further into history to see what evidence nosotros can notice to aid united states of america better empathize longer term trends in mine productivity and the factors driving them. The objective is to identify the factors which accept shaped the tendency rather than those which have shaped variations around that trend. Nosotros volition and then, more than speculatively, consider whether the factors which appear to have contributed to boosting productivity in the past have the capacity to continue to heave it into the future. We will also consider the role that newer, digital technologies associated with what is being called the 4th industrial revolution, might be able to play in sustaining productivity growth in mining at past levels.

Long-term trends

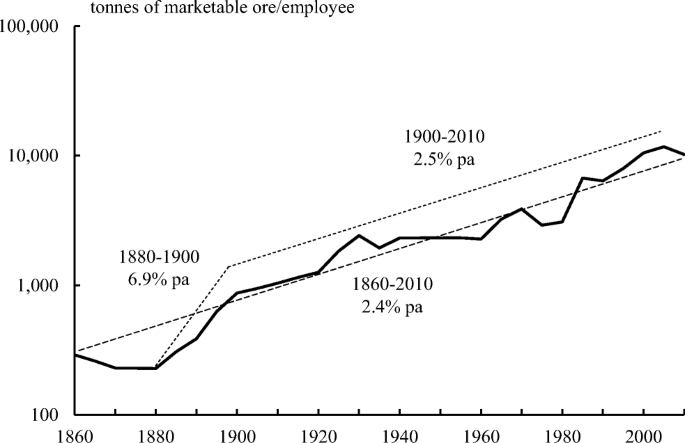

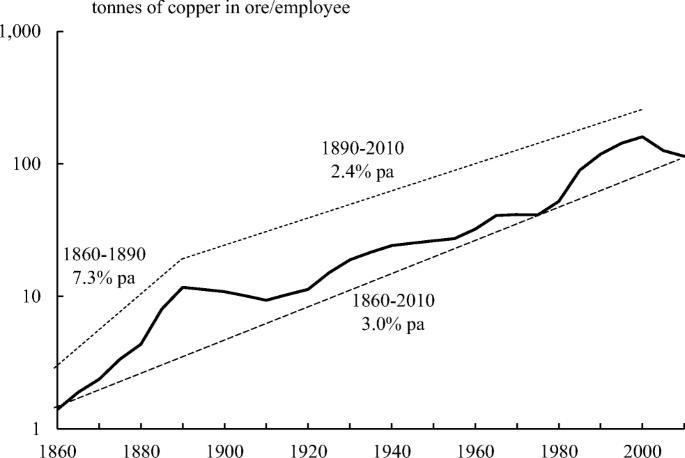

A few years ago, in the context of an investigation into the notion of sustainable evolution, I adult an analysis of labour productivity in US atomic number 26 ore and copper mining going back over one hundred years, using data derived from the US Bureau of the Census (Humphreys 2001). These information have been updated and are presented in Figs. 2 and three. A logarithmic scale has been used in the figures to emphasise trends and changes in trend.

Productivity growth in US iron ore mining. Source: US Bureau of the Census, USGS

Productivity growth in U.s.a. copper ore mining. Source: US Bureau of the Census, USGS

These information are not without their limitations. The census data are irregular, in general available only at 5-year intervals and, in earlier times, are fifty-fifty more irregular nevertheless. Footnote 1 They are also data from only one country and two commodities and the data are only for labour productivity, non MFP.

Then once more, on the positive side of the account, the USA is a very big state which has had a large and important mining manufacture throughout the period covered, and copper and iron ore are 2 of the nigh important commodities mined. Moreover, because of the open up, competitive, nature of the US economy, the odds are skillful that developments in the USA are a wide reflection of trends in the industry globally. Most compelling of all, they are the only consistent data serial we have!

The starting time matter to observe from the figures is that although in that location have certainly been variations over the period, the overall impression of productivity growth for both commodities is one of stability and continuity. For iron ore, the boilerplate annual growth in labour productivity over the menstruum 1860–2010 is two.4%. For copper, information technology is around three% a yr, although it should exist noted that productivity for copper is measured in relation to copper in ore mined, not gross copper ore. Given that copper ore grades declined over this period, a fairer measure of productivity would be copper ore mined or milled per worker, rather than copper contained in the ore. It has not been possible to exercise this here but our earlier work, up to the 1997 survey, suggested that this would have pushed productivity about a percentage signal higher still, i.east. nearer 4%. This is a pretty impressive achievement.

The 2nd thing to discover is that, notwithstanding the consistency of productivity growth over most of the period covered by the figures, there does announced to have been something of an acceleration in the charge per unit of productivity growth during the late nineteenth century, betwixt 1860 and 1890 for copper (when labour productivity grew at slightly over 7% a year) and between 1880 and 1900 for atomic number 26 ore (when it grew at about vii%).

The reason for this is not hard to find. The latter part of the nineteenth century was the launch pad for the second industrial revolution, a revolution rooted in electrification, motorisation and the beginnings of mass industrial production. Footnote 2 Mining, with its need to drill, to dig and to haul could take been made for this revolution, and gradually the manufacture figured out how all-time to apply the technologies and equipment becoming available to information technology.

Steam shovels were introduced in 1892 to mine iron ore in the Mesabi Range in Minnesota and in the following years, they began to exist adopted more widely beyond the The states mining industry, notably in copper and in coal. They were also exported from the U.s. to copper mines in Spain (Rio Tinto), Republic of chile (Chuquicamata) and the Congo (Kambove in Katanga). About famously, they were deployed at Utah Copper'due south Bingham Canyon'southward mine, which started up in 1906. This was a landmark development which demonstrated how technology could be harnessed to mine and process, on a large scale, low grade porphyry copper ores which had not until so been deemed economic to work (Marsh 1920; Lynch 2002). Combined with powerful new crushers and grinders to break downwards the ores, Wilfley tables (invented in 1895) to perform gravity separation, and froth flotation (introduced in 1910) to concentrate the copper, this heralded a revolution in the mining industry and a breakthrough bound in mine productivity (Lynch 2002). During the same period, the mining of gold was existence transformed by the introduction of bucket dredges.

The 3rd affair to observe is that there is the suggestion in the last few years of a slowdown in productivity growth. This is consequent with the data trends shown in Fig. 1, although, given the irregular nature of the demography data, it cannot exist considered conclusive. In my before paper, before this slowdown showed, I took the view that, on the basis of the information then available, there was no reason to suppose that productivity growth in the manufacture would not continue to follow the same trajectory information technology had for the preceding one hundred years.

Developments in mining equipment

Industrial revolutions do not come nearly overnight. It oftentimes takes many years for the technological breakthroughs that such revolutions make possible to exist properly understood and their attributes exploited.

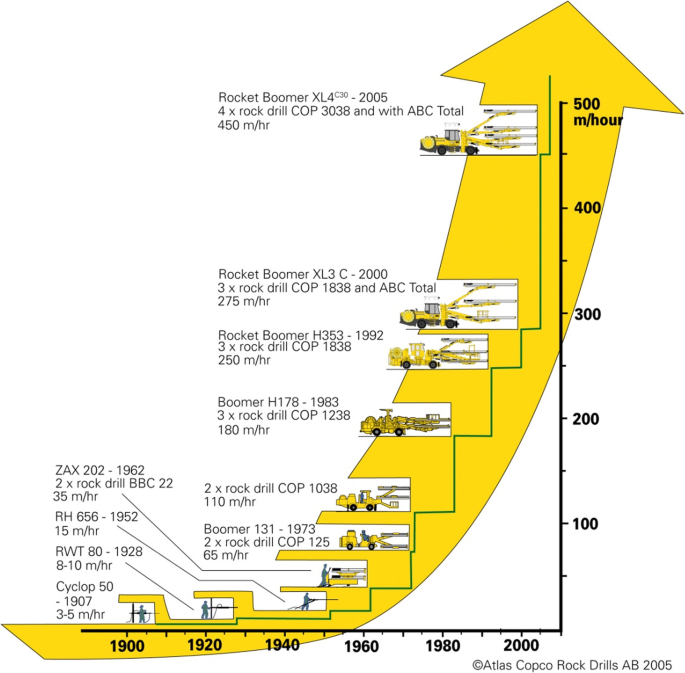

The longer term impact of the 2d industrial revolution on mining and mining productivity can possibly be appreciated in part past looking at developments in mining equipment. Mention has already been made of the introduction of power shovels in the 1890s (steam was replaced in afterwards years by diesel power). In this section, we wait at trucks and drills.

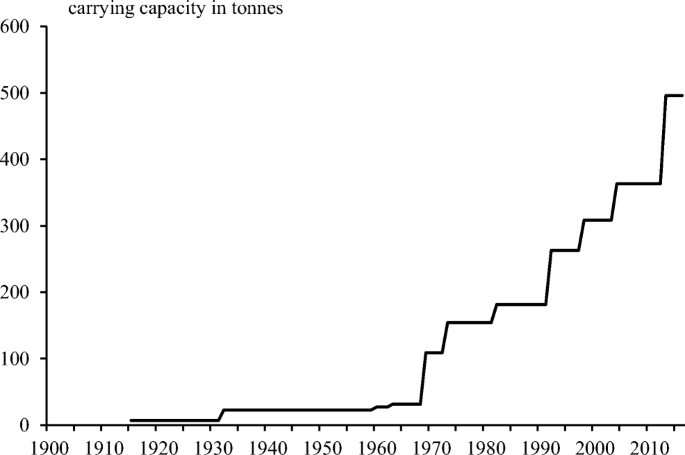

After mineral ores have been broken out of the surrounding rock using explosives and scraped upwardly past power shovels, then the key challenge is to go them to the crushers and thence to the mill. For this, one needs a armada of trucks.

Early trucks were very pocket-size by today's standards. A breakthrough in truck technology came in 1915 with the introduction of the Mack Model AC 'Bulldog', a truck with a carrying capacity of half dozen.8 t (vii.5 brusk tons). This became the workhorse of the mining industry and was produced until the finish of the 1930s, albeit that by and then Mack had introduced (in 1932) the Model AP which could bear upwardly to 22.vii t (25 short tons) (Haddock 1998).

Although truck capacity connected gradually to amend, at the start of the 1960s, the largest truck bachelor to miners was still but 27.2 t (30 short tonnes), i.e. four times the size of the Mack Bulldog. From here on, nevertheless, as Fig. iv illustrates, the pace of truck development increased dramatically, and then that today the largest truck available has a conveying chapters of almost 500 t. This is eighteen times the size of the largest truck available at the start of the 1960s, potentially representing a substantial increase in mine productivity.

Mine truck capacity: introduction date of largest haul truck on the marketplace. Source: Manufacture sources

A similarly dramatic evolution appears to take taken place in drilling technologies, as Fig. 5, based on an analysis past Epiroc (formerly Atlas Copco) illustrates. Over the ane hundred years (1907–2005) covered by the figure, drilling rates increased from three to 5 g per hour to 450 thousand per hour, an increase of one hundred fold. By comparison with the growth of truck size, the developments in drilling appear to have been a fleck more even through time, although in that location is still bear witness of an acceleration during the second half of the period. While drilling rates increased ninefold between 1907 and the early 1960s, they increased 13-fold betwixt 1962 and 2005.

Growth in drill capacity over one hundred years. Source: Epiroc/Atlas Copco

Economies of scale

Going paw in hand with the increasing size and quality of equipment has been an increase in the size of mines. This permitted the deployment of larger and more productive equipment as well equally helping to reduce unit costs of production by helping to spread fixed costs over larger tonnages. Scale in mining is, in effect, the equivalent of mass production in manufacturing.

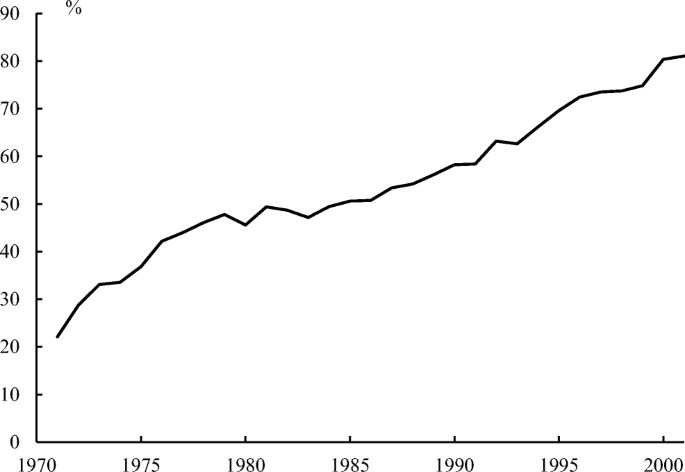

Although there tin can be little doubt that mines have generally got bigger over fourth dimension, the bear witness to illustrate and quantify this beyond the industry is hard to come by. Databases characterising the production and costs of the mining industry just really started to become available in the 1970s and industry-level data earlier this is patchy. Given, however, that some of the biggest gains from scaling upwards appear to have come up in the post–World State of war II flow, this may not exist likewise serious a constraint.

Figure 6 shows that big copper mines, defined here as those producing over x one thousand thousand tonnes of ore a year, increased their share of global copper output from 20% in 1970 to 80% in 2000. Footnote 3 Other data sources confirm this trend. Crowson (2003) found that betwixt 1976 and 2000, the mean size of the world's copper mines grew 182% and the size of the median copper mine grew 252%. The comparable numbers for zinc mines over 1980–2000 were 117% and 133% respectively. The moving picture for gold was a little unlike. Mean mine size went down ii% but the median went up 131% betwixt 1975 and 2000. This design probably reflected the closure of big South African mines during this period.

Share of world copper produced by mines mining x million tonnes a year. Source: Humphreys 2001

Imperfect as these information are, they are sufficient to make the signal that mine size increased dramatically over the twentieth century, beingness both facilitated past, as well as creating opportunities for, the deployment of larger and larger equipment. Almost certainly, it was a major contributor to improvements in mine productivity.

It is unclear whether this trend has continued into the twenty-first century but is information technology possible that it has not. In the example of copper, the twenty-kickoff century has not yet seen the opening of any new mega mines on the calibration of Grasberg (started 1973), Escondida (1990) or Collahuasi (1999). Moreover, there is some evidence from exploration data that copper discoveries are getting smaller. Research by SLN Metals Economics Grouping (since incorporated into South&P Global Market place Intelligence) revealed that the average size of copper deposits constitute declined from 5.8 million tonnes of ore in the period 1990–1994 to 3.8 million tonnes of ore during the period 2005–2011 (Chender 2012). The same research revealed that gold found in major discoveries fell steeply betwixt the mid-1990s and the tardily 2000s. More recent research from S&P Global Market Intelligence confirms that these trends continued through to 2017 (Mining Journal 2018b).

Other factors

The increasing calibration of mines and of the equipment used in them are adequately obvious contributors to productivity. Developments in transportation take also made an of import contribution, especially for the bulk bolt similar coal and iron ore. The toll of runway freight has fallen substantially over the years. According to the OECD, the toll of maritime freight in real terms halved betwixt 1870 and 1930 and roughshod some other 80% betwixt the 1930s and 2000, this largely because of the growth in ship size and in item the widespread use in recent years of Capesize vessels for dry bulk commodities (Huwart and Verdier 2013). These developments in transportation take in plough facilitated the opening up of rich but remote mineral deposits which it might not otherwise have been economic to develop. The iron ore deposits of the Pilbara in Western Australia and those in Amazonia in Brazil stand as examples of this.

But there are other factors which are harder to pin down and to measure. A major input cost to mining, oft the second most important after labour, is the supplies a mine buys in. These tin can range from tyres, auto spares and explosives to structure raw materials and chemicals. In every bit far as the sectors that produce and sell these things strive to heave their ain productivity, there is the potential for increases in the functioning of these bought-in products, arising from innovation and technological alter in those sectors, to menstruum through into an increment in mine productivity. Although it is true that changes in the quantity of intermediate inputs to mining are taken into account in computing MFP, it may well be that such calculations practise not fully capture changes in the quality of inputs or, therefore, the elevator that they tin requite to mine productivity.

There is also the issue that contributions to productivity can be overlapping. We take already noted that larger mines and larger equipment are, in a sense, two sides of the same coin. Some improvements in productivity which ane might put down to the exertions and ingenuity of the miners may in fact reflect the effects of increased contest stemming from globalisation or from changes in authorities regulations. Also to be factored is the inertia which arises from the fact that high quality, low-cost resource endow their owners with an enduring competitive advantage. (Explaining why, in stark contrast to many industrial sectors, the same companies, BHP, Rio Tinto and Anglo American, have been leaders in the industry for generations.)

Perhaps most problematic of all is the contribution of direction to productivity. Intuitively, it seems highly probable that a key chemical element in boosting productivity lies in the power of direction to pull all the various factors of product, capital, labour and intermediate products together in an effective and disciplined fashion. Moreover, the data systems that they employ to monitor what is going on and to assist with controlling must also play a part in this procedure, mayhap an increasing one. Unfortunately, we can only infer this from the progress of productivity; it is nearly impossible to measure directly. Indeed, most of the factors which contribute towards changes in MFP report collectively in what is known statistically every bit the 'Solow residual', after all the directly measurable inputs like labour and uppercase have been taken into account, and are not hands disentangled (Solow 1957).

Tentative conclusions from the long-term history

From the data presented, information technology is evident that the mining industry has been remarkably successful over the last one hundred and fifty years in raising its productivity. And the fact that productivity growth has been cyberspace positive throughout near all of this menstruation implies that the industry has done an constructive job in offsetting the tyranny of depletion. At the heart of this success, as John acknowledges in his work, has been the advancement and application of engineering science.

The journeying through time has, however, been an uneven one. The data on US mining suggests that the initial adoption of second industrial revolution technologies resulted in a surge in industry productivity. In today'due south parlance, i might phone call this the expression of 'confusing' evolution. The subsequent, slower, tendency in productivity growth (particularly deadening in the case of the US fe ore industry through the 1940s to the 1970s it might be noted) points to a more gradual absorption of new technologies and a multiplicity of contributing factors. Unpublished research conducted in Rio Tinto in 2000 suggested that a cardinal driver for this tendency was the gradual displacement of labour by capital and energy, this in turn reflecting a sustained shift in relative factor prices, the falling toll of machinery and of energy on the one hand and ascension existent incomes on the other.

The variation effectually the trend in productivity growth since its initial surge seems, every bit John has demonstrated, been significantly shaped past commodity cost cycles. Periods of astute price pressure have stimulated sharp increases in productivity, such as those in U.s.a. copper in the 1980s and in fe ore mining pretty much everywhere during the same decade (Tilton 2014; Topp et al. 2008). This is downwardly to a raft of factors ranging from worker layoffs, operational improvements and the lagged effects of earlier investment. During periods of high prices, by dissimilarity, when mining companies have a tendency to focus on volume growth rather than unit efficiency, productivity has a tendency to reject.

In assessing what is driving electric current productivity performance and determining where things are probable to be headed in the future, it is necessary to separate out secular and cyclical influences. Is the recent apparent decline in productivity but a cyclical phenomenon which will in time contrary or might it herald a break in the secular trend? The answer to this is rather important since it potentially has implications for the manufacture'south chapters to offset the furnishings of depletion in futurity. We need, in effect, to endeavor to wait through the cyclical variations.

If we focus down on the things which we take identified as primal drivers of the long-term, secular, tendency in productivity, in that location are some worrying indications that they may be losing their forcefulness.

First, the increasing scale of mines along with the deployment of always larger machinery have played what is surely an indisputable role in boosting industry productivity. But, it is hard to see these factors playing the same role in the future. The manufacture is simply not finding and bringing on the big mines that could take this to a whole new level. For some niche commodities important to modern technologies, big-scale deposits may only not exist. While we tin can doubtless expect comeback in truck technology in the future, it is hard to believe that truck carrying chapters will, or indeed could, increment eighteen times over the side by side l years. The same consideration applies to advances in shipping. Eventually, with any given technology, one runs upward against the constraints of immutable physical laws. In addition, equally already indicated, the data we have bachelor to us suggests that exploration discoveries are generally getting smaller and the cost of finding a unit of economically recoverable mineral is increasing (Koch et al. 2015).

Second, information technology has been suggested that an of import factor driving productivity increases in the past has been capital-labour exchange, a tendency supported by the declining costs of capital and energy relative to labour. It is, of course, hard to know how the costs of these factors will develop in the time to come. The expectation (or, at any rate, hope) must be that labour costs will continue to rise equally standards of living increase. Notwithstanding, the situation for energy is very unclear. Information technology is entirely possible that energy prices will have to rising in time to come to reflect the cost of carbon emissions resulting from the use of hydrocarbons and to incentivise investment in carbon-free ability generation.

A third concern is that the global economic system has been subject area to some essentially non-repeatable events which have fostered and reinforced productivity growth in the mining manufacture and other industrial sectors only which, having happened once, cannot happen again. Here, I am thinking of the opening up of investment opportunities which accept followed on from economic globalisation, likewise as the intense competition which flows from more open global markets. Transactional costs of international merchandise have fallen dramatically in the post–World War II era (Huwart and Verdier 2013). I am also thinking of the dramatic changes in global financial markets which have permitted the financing of very large upper-case letter-intensive projects, such every bit mines, even in quite loftier-hazard countries. In curt, a geopolitical surroundings characterised by greater nationalism and protectionism may not be as conducive to the growth of mining manufacture productivity as take been the conditions experienced over the past half century.

Impacts of the 3rd and fourth industrial revolutions

Of course, we cannot rule out that, as the old drivers of productivity weaken and play out, and then new ones will emerge to take up the baton of productivity growth in mining.

We talked before about the dramatic effect that the appearance of the 2nd industrial revolution had on productivity in mining. Conventional wisdom has it that since the ructions of the second industrial revolution, there have been two further revolutions. The third industrial revolution was a digital revolution and is generally viewed as having been launched in the 1960s or 1970s. This revolution marked the transition from analogue, electrical and mechanical devices to digital technologies. It is associated with personal computing, the Cyberspace and advances in data and communications technologies (ICTs) (Table ane).

More recently, a view has formed that we may be entering a fourth industrial revolution, sometimes referred to every bit Industry 4.0 (Schwab 2017). This builds on the third revolution and is characterised by technologies which integrate the concrete, digital and biological spheres. Features of the new revolution are robotics, bogus intelligence, blockchain, nanotechnology, quantum computing, biotechnology, the Internet of Things (IoTs), 3D printing and autonomous vehicles. Its impacts on production, management and society are commonly talked virtually in terms of their chapters to 'disrupt' existing practices and behaviours.

That these more than contempo revolutions will take, indeed already have had, an impact on the mining manufacture is not in doubt. The crucial question though is not whether they will accept an impact merely whether they will have the aforementioned kind of impact on the industry as the second revolution and accept sufficient forcefulness to proceed productivity on an upwardly path in the face up of countervailing pressures from depletion.

The tertiary revolution has been with u.s.a. some time. Advances in computing have, without doubtfulness, played a useful role in improving mine planning, truck scheduling, maintenance efficiency, process control, price monitoring and project assessment amidst other things, while developments in communications technologies have facilitated management oversight, helped meliorate safety and assisted with procurement and sales. However, information technology would be hard to maintain that in that location was anything truly transformational about these changes. They would appear to accept made a useful contribution to the ongoing incremental comeback in productivity which the industry experienced through the 1980s and 1990s but they practice not announced to have had sufficient forcefulness to prevent the subsequent refuse in productivity. Certainly, there is nothing in the data we have on productivity to advise an impact of the sort delivered by the onset of the second industrial revolution in the late nineteenth century. The tertiary revolution seems to take been more about the optimisation of existing technologies than about technological quantum.

There is currently much hope vested in the possible impacts on mining manufacture productivity of the fourth industrial revolution. A recent survey of CEO stance on drivers of hereafter industry transformation indicated that industry leaders expect digitisation to exist the principal commuter of future change. Third on the listing of drivers was falling ore grades (Mining Journal 2018a). The perspective of the CEOs appears to exist rooted in the potential that the new technologies could have on enabling mines to work more intelligently, from the deployment of democratic machinery to the wholesale networking of mines into single, interconnected and optimised entities. 'Smart', it has been said, 'is the new big'.

In 2016, the merchandise journal Mining Magazine conducted an extensive survey on the specific technologies which mining companies believe will take most affect on the industry—its profitability, productivity and rubber—in the futurity. More 120 mining companies responded to the survey. The results are summarised in Table 2.

Leading the list of technologies expected to take a major touch on the industry over a 5- to 10-year horizon were those related to improvements in remote geological surveying using satellites and drones, together with improved imaging. (HP is 'high powered'.)

The biggest contributions to increased performance on the production side of the business organization were expected to come from the awarding of high powered computing and big data - a shift to 'intelligent mining'. The key here is the generation of real-fourth dimension information on every conceivable aspect of mining operations and the utilize of these information to bring about lean, factory-style production, reducing reanimation, saving energy, increasing safe and boosting output.

A second cluster of technologies—the Internet of Things and operating applied science-data applied science (OT-IT) integration—is focused on linking all aspects of a business together into a seamless whole, collaborative Information technology as information technology is sometimes called. Different factories, conditions in a mine are shaped past nature and are constantly irresolute, so information and direction systems have to exist continuously adapting. Amend integrated, real-time systems are seen as potentially unlocking large productivity gains by improving maintenance, mine planning and nugget utilisation.

Interestingly, some of the more than visible technologies, including automation and remote mining, appear further downwardly the list, as exercise such physical technologies every bit pre-concentration, in-pit crushing and conveying systems, and improved blasting techniques.

Commenting on such developments, the head of growth and innovation at one of the world's largest mining companies is quoted as saying, 'Data is the new oil … . Every bit an industry we have achieved incredible things through scaling and always refining known technologies. The Tech 4.0 digital disruption is now starting to manifest in a significant way upon our industry. From cloud computing, to new sensors, to drones, to ever more automation and at present the rising of automobile learning and AI. This is all being fused together through data science to generate new insights' (Roberts 2018a).

Collectively, these technologies hold considerable promise and some of them are already being operationalised. Autonomous trucks and driverless trains are already a reality in the industry. Nevertheless, their full potential has yet to be realised and their capacity to contribute a significant boost to productivity is unproven. In add-on, they heighten some awkward structural questions about the mining industry. Many of the groundbreaking technologies beingness developed are not the products of the mining industry itself simply of the Mining Equipment and Engineering science Services (METS) sector. This makes mining companies increasingly dependent of the efforts of others for their success, forcing a reassessment of what constitutes their core skills prepare and competitive advantage (Buia et al. 2018).

Future directions

There is little question that the second industrial revolution brought nearly massive improvements in mining industry productivity. After revolutions take supported these developments but, despite the rhetoric of 'disruption' which accompanies the almost recent revolution, they accept not, or at least have non even so, proved transformative in the aforementioned mode or to the same caste. It is possible that this is but a affair of time. Many of the benefits of the 2nd revolution took years to come up through, during which there were sustained periods of depression (and negative) productivity growth (for case in US copper in the 1890s and 1900s and in Us atomic number 26 ore in the 1940s and 1950s). But, then once again, information technology is besides possible that the mechanical basis of the second industrial revolution gave it a special relevance to, and bear on on, mining because of the industry'southward essential nature every bit a physical, earth-moving and processing, activity.

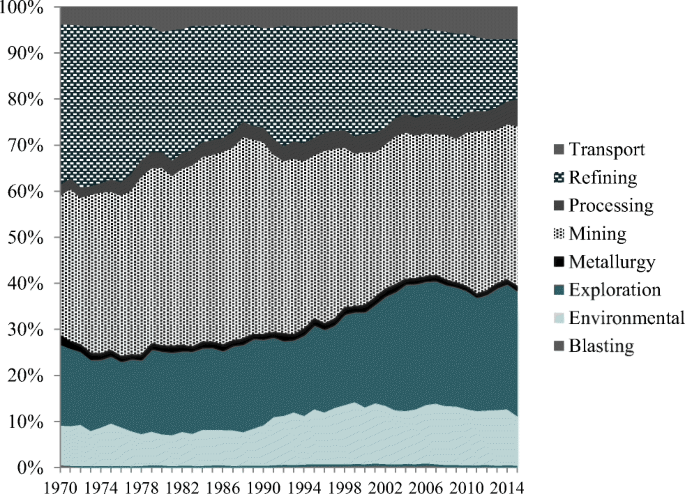

To put it in another mode, while mining, along with manufacturing, may have been a particular beneficiary of the second industrial revolution, it may be that the primary benefits of the other industrial revolutions lie elsewhere. The beginning industrial revolution wholly transformed man's power to elevator and to move things past harnessing the power of coal to replace beast musculus in transport and structure. The primary value of the third and fourth revolutions, which transform our capacity to compute and communicate, may prevarication in other economic sectors, for instance in medicine, in design, in social media, in travel and in biotechnology. Information technology is perhaps significant that, in the Mining Magazine survey shown above, the area where the industry expects the fourth revolution to have its greatest impact is not really in mining but in exploration, a fundamentally more knowledge-based activeness. In this context, it is interesting to note that, in recent years, the patenting of exploration technologies has, along with the patenting of ecology technologies, grown faster than any other mining-related technologies (Fig. 7). Every bit for the business of mining itself, it may turn out that the quaternary industrial revolution will deliver some useful full general purpose technologies, similar AI (patents for which take grown rapidly in contempo years but are not included in Fig. 7), but may not exist transformative in the way that the 2d revolution was.

Limerick of mining innovation, measured by patents filed. Source: Daly et al. 2019

Concerns about productivity are not, of course, confined to the mining industry. Slowing productivity is a widespread feature in many advanced economies (OECD 2014; Economist 2016). Moreover, economists have for some time raised questions about the impact of developments in ICT on economical productivity, with Robert Solow famously quipping about existence 'able to run across the computer age everywhere simply in the statistics' (Solow 1987). It is unclear where the caption for this lies, whether the problem is real and the performance of new technologies simply are not what they are claimed to be (peculiarly when compared to the transformative ones of before eras), whether we take a problem with measurement of outputs in economies with a high intangible component, or whether the introduction of new technologies works with very long lags and that we are experiencing the lull earlier the storm (Wolf 2018).

The objective of this article is not to debate that productivity growth in mining is in terminal decline and that article prices must therefore rise. Rather, information technology is to investigate the longer term technological drivers of productivity in the manufacture and to point up the calibration of the challenge the industry faces in reversing the recent reject in productivity. It is besides to question whether the succeeding waves of technological change represented by the iv industrial revolutions have similar relevance to this detail economic sector. My conclusion is that they probably practise non and that the more recent revolutions, while they volition be supportive of productivity developments, may struggle to evangelize the same quantum improvements that the industry was able to extract from the earlier ones.

We cannot say for certain where future changes in the industry will come from and the form they will accept. It is true that, over the years, the manufacture has had an impressive rail record of finding ways to defy the odds and combat the tyranny of depletion. And, for most of history, it has not washed to bet against the ingenuity of the human race. However, it is as well true that mining is an manufacture which suffers from considerable inertia because of its upper-case letter-intensive nature and because of the inbuilt competitive advantage which resides in certain high-quality resources. Information technology has been suggested that the touch of the quaternary revolution may be incremental at large existing mines with their sunk upper-case letter and given footprints, merely may take more scope for awarding in smaller, more flexible, more selective, automated mines that exploit variability and have a much lower social and ecology impact. In that location may also be telescopic for technological breakthroughs in direct disintegrating mineral grains in rocks to reduce free energy inputs and waste, in advanced fragmentation using new blasting techniques and in majority sorting to eliminate waste earlier in the product process (Roberts 2018b).

While such developments may be disruptive in the sense that they change the modus operandi of the manufacture, shift its policy focus or lead it to supply new, more than technologically, sophisticated markets, it is far from clear how they could disrupt, or transform, manufacture productivity. True disruption is about innovations which create new markets and value networks and readapt existing markets and networks. Information technology involves, in effect, a new value proposition for customers and investors. I tin see the effects of this clearly enough in areas like retail and media (and even in oil where the advent of fracking has shaken up the global industry) but the application of the thought to mining requires a chip more imagination.

Disruption for mining productivity has to be about a fundamental pace change in the relationship betwixt inputs and outputs. In the past, the value proposition of miners has typically been found in the delivery of cheaper raw materials achieved through a relentless focus on the efficient direction of inputs. It would be incorrect to suppose that we take exhausted the scope for doing this. However, if, as seems possible, the power to attain substantial new gains in this area is diminishing, then the manufacture may accept to explore other avenues to extract value. It might, for case signal to mining companies seeking, and being able, to secure premiums for their products by branding based on the responsible and sustainable manner of their production. Or it might involve companies 'renting out' their products for the life of the goods into which they are incorporated rather than selling them, thereby positioning themselves equally pivotal players in the circular economic system. In other words, it may lie not in increasing the efficiency of use of inputs just discovering ways to promote the value of outputs.

The outcome matters. While the scale of the challenge will vary amongst commodities, pressures from depletion are unlikely to allay and may well intensity. Although it goes beyond the telescopic of this article, there is some evidence that depletion may be non-linear and that the challenges faced by productivity in offsetting depletion are set up to go materially harder (Mitra 2018). If productivity in the mining industry does not increase to come across it, and then mineral prices must rise. This is not a affair nigh whether one is an optimist or a pessimist. Rather, it is about having an appreciation of how things worked in the by and adopting a difficult-nosed view about whether information technology is reasonable to assume that what applied in the past is probable to utilize in the futurity. What cannot be doubted is that the mining industry is going to have to work very hard and to be very creative to maintain the momentum of its past productivity operation.

Notes

-

Because of the irregularity of census surveys, adjustments have been made to the data to make them more manageable and to fill in some gaps. Thus, census information accept been allocated to the nearest 5-yr interval, so that they all appear to come up at the beginning or in the middle of a decade (thus, 2012 survey data take been allocated to 2010), and gaps in the earlier years have been filled by interpolation on a straight line basis. In the nearly contempo census surveys, production data take been withheld so these accept had to come from other sources. With regard to employment, reported data on copper in the well-nigh recent surveys include also employment in nickel mining, but, since this is likely to be small in the United states, it has been overlooked. At the time of writing, results from the 2017 census had not been made publicly bachelor.

-

The first industrial revolution, based largely on developments in coal, iron and textiles, launched in the second half of the eighteenth century. Mining in this era was essentially a transmission activity with transport provided by animals and, subsequently, canals and railways. Vestiges of this sort of mining persist amongst artisanal and pocket-size miners (ASMs).

-

The data in this effigy came from the Rio Tinto Mine Data Arrangement. Information technology could not exist updated since the system no longer exists.

References

-

ABS (2018) Australian Bureau of Statistics. Available at: https://www.abs.gov.au. Accessed 5 Sept 2018

-

Barnett H (1979) Scarcity and growth revisited. In: Smith VK (ed) Scarcity and growth reconsidered. Johns Hopkins University Press for Resource for the Future, Baltimore

-

Barnett H, Morse C (1963) Scarcity and growth: the economics of natural resource availability. Johns Hopkins University Press for Resources for the Future, Baltimore

-

BHP (2014) Focusing on operating and capital productivity. Available at: https://www.bhp.com/media-and-insights/reports-and-presentations/2014/eleven/focusing-on-operating-and-capital-productivity. Accessed September 2018

-

BLS (2018) US Agency of Labor Statistics. Available at: https://world wide web.bls.gov. Accessed 5 Sept 2018

-

Buia C, Heyning C, Lander F (2018) The risks and rewards of outsourcing. McKinsey&Company. Available at https://world wide web.mckinsey.com/industries/metals-and-mining/our-insights/the-risks-and-rewards-of-outsourcing. Accessed September 2018

-

Chender 1000 (2012) What does the adjacent generation of opportunities look like? Presentation to Mines & Coin conference, London

-

Crowson P (2003) Mine size and the construction of costs. Resour Policy 29:ane–2

-

Daly A, Raffo J, Valacchi G (2019) Recent trends of innovation in the mining sector. In: Daly A, Humphreys D, Raffo J, Valacchi Chiliad (eds) Global challenges for innovation and IP in the mining industries. Cambridge Academy Printing, Cambridge forthcoming

-

Deloitte (2014) Mining spotlight on: sliding productivity and spiraling costs. Bachelor at: https://www2.deloitte.com/content/dam/Deloitte/global/Documents/Free energy-and-Resources/gx-er-sliding-productivity-and-spiraling-costs.pdf. Accessed September 2018

-

Flesher Northward, Moyo M, Rehbach S, van Niekerk E (2018) Productivity across the global mining sector is starting to improve. McKinsey&Visitor. Available at: https://www.mckinsey.com/industries/metals-and-mining/our-insights/productivity-beyond-the-global-mining-sector-is-starting-to-amend. Accessed September 2018

-

Haddock K (1998) Giant earthmovers. MBI Publishing, Minneapolis

-

Humphreys D (2001) Sustainable development: can the mining industry beget information technology? Resour Policy 27:1–7

-

Humphreys D (2013) Long-run availability of mineral commodities. Miner Econ 26:i–2

-

Humphreys D (2018) The mining industry later on the boom. Miner Econ. Available online April 2018

-

Huwart JY, Verdier L (2013) Economic globalisation: origins and consequences, OECD Insights. OECD Publishing. Available at: https://www.oecd.org/insights/economic-globalisation.htm. Accessed September 2018

-

Koch A, Schilling D, Upton D (2015) Tackling the crunch in mineral exploration. The Boston Consulting Group. Bachelor at: https://xmbl.files.wordpress.com/2015/11/bcg-tackling-the-crisis-in-mineral-exploration-june-2015_tcm80-192050.pdf. Accessed September 2018

-

Lala A, Moyo K, Rehbach Southward, Sellschop R (2016) Productivity at the mine face: pointing the way forward. McKinsey&Company. Available at: https://www.mckinsey.com/industries/metals-and-mining/our-insights/productivity-at-the-mine-face-pointing-the-way-forward. Accessed September 2018

-

Lynch M (2002) Mining in globe history. Reaktion Books, London

-

Manthy RS (1978) Natural resources commodities: a century of statistics. Resource for the Future, Washington DC

-

Marsh R (1920) Steam shovel mining. MacGraw-Hill, New York

-

Mining Journal (2018a) Global leadership report: preparing for transformation

-

Mining Journal (2018b) Copper finds are drying up, online edition xiv Baronial 2018. Available at https://www.mining-journal.com/research/news/1344549/copper-finds-are-drying-up. Accessed 14 Baronial 2018

-

Mining Magazine (2016) Mining engineering and the culture modify, September 2016

-

Mitra S (2018) Depletion, technology and productivity growth in the metallic minerals industry. Miner Econ. Available online Nov 2018

-

OECD (2014) Productivity's wave adieu? OECD Observer No 300, Q3 2014. Available at: http://oecdobserver.org/news/fullstory.php/aid/4558/Productivity_92s_wave_goodbye_.html. Accessed September 2018

-

Roberts R (2018a) Rio's McIntosh says miners take need for dissimilar future. Min J. 14 May 2018

-

Roberts R (2018b) Hereafter of mining. Min J. x July 2018

-

Schwab K (2017) The fourth industrial revolution. Crown Publishing Grouping

-

Solminihac Hde, Gonzales LE, Cerda R (2018) Copper mining productivity : lessons from Chile. J Policy Model 40

-

Solow RM (1957) Technical change and the production function. Rev Econ Stat 39

-

Solow RM (1987) We'd better watch out. New York Times Volume Review. 12 July 1987

-

The Economist (2016) Doing less with more, 19 March 2016

-

Tilton JE (2014) Cyclical and secular determinants of productivity in the copper, aluminum, fe ore, and coal industries. Miner Econ 27:1–19

-

Tilton JE, Landsberg HH (1999) Innovation, productivity growth, and the survival of the US copper industry. In: Simpson RD (ed) Productivity in natural resources industries. Resource for the Future, Washington DC

-

Topp V, Soames L, Parham D, Bloch H (2008) Productivity in the mining industry: measurement and interpretation. Australian Government, Productivity Commission, Staff Working Paper, Melbourne, VIC

-

Wolf Yard (2018) The long wait for a productivity resurgence. Financial Times. 12 June 2018

Author data

Affiliations

Corresponding author

Additional information

Publisher's annotation

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

OpenAccess This article is distributed nether the terms of the Creative Eatables Attribution 4.0 International License (http://creativecommons.org/licenses/past/four.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided yous give appropriate credit to the original writer(s) and the source, provide a link to the Artistic Eatables license, and indicate if changes were made.

Reprints and Permissions

About this article

Cite this commodity

Humphreys, D. Mining productivity and the fourth industrial revolution. Miner Econ 33, 115–125 (2020). https://doi.org/10.1007/s13563-019-00172-9

-

Received:

-

Accepted:

-

Published:

-

Upshot Appointment:

-

DOI : https://doi.org/10.1007/s13563-019-00172-nine

Keywords

- Mining

- Fourth industrial revolution

- Productivity

- Depletion

- Digitisation

- Mining costs

cardenasevied1952.blogspot.com

Source: https://link.springer.com/article/10.1007/s13563-019-00172-9

0 Response to "What were the major contributors to the new productivity in the late nineteenth century?"

Post a Comment